Striving for Sustainability in Surface Engineering (SSSE24)

Thursday, 25 April 2024 (9am – 5pm)

University of Nottingham (A09, ESLC)

TSSEA’s 2024 conference on Striving for Sustainability in Surface Engineering (SSSE24) will be the UK’s foremost conference for thermal spray and surface engineering researchers, engineers, technicians, industrialists and managers. The 1-day conference will cover the whole spectrum of thermal and cold spray technologies and other surface engineering solutions. This year, the conference has a dedicated focus on sustainability and how the sector is gearing up to achieve NetZero in line with government and global priorities. Topics will cover processing-microstructure-properties relationships, new and innovative coating applications, new compositions, industrial solutions in wear, corrosion, thermal protection, sensors, diagnostics, and many more.

Join us at Nottingham to network, visit the facilities and discuss with the industry and academic leaders.

Why should you attend?

TSSEA conference in 2024 will feature:

- 15+ invited speakers from sector leaders from Universities, Industry and RTOs

- In-depth technical talks from academic experts on thermal spray and surface engineering

- Insightful talks from Industry Leaders on cutting-edge topics shaping our lives in the 21st century

- Dedicated networking time over coffee/tea and buffet lunch

- Visit to the state-of-the art facilities at the Centre of Excellence in Coatings & Surface Engineering (CE-CSE) and Nanoscale and Microscale Research Centre (nmRC) at the University

- An industry forum moderated by TSSEA industry experts

- An exhibition space to showcase thermal spray and surface engineering

- A poster session by early career professionals

- And much more!

Our growing list of invited confirmed speakers includes:

- Prof John Nicholls, FREng, Professor of Coatings Technology, Cranfield University

“Towards Smart, Sustainable Coatings: Self-diagnostic TBCs and EBCs” - Prof Ping Xiao, Chair of Rolls-Royce/Royal Academy of Engineering Research Chair, Chair of IOM3 Surface Technologies Group, University of Manchester

- Prof Nadimul Faisal, Professor of Surface Engineering & Micromechanics, Robert Gordon University

“Thermally Sprayed Multi-material Electrode Manufacturing for Electrolysis” - Prof Saurav Goel, Professor of Manufacturing and Associate Director of the EPSRC Networkplus in Digitalised Surface Manufacturing, London South Bank University

- Dr Mingwen Bai, Assistant Professor of Surface Engineering, University of Leeds

“Investigating Cracking Dynamics in Thermal Barrier Coatings: An In-Situ SEM and Image-Based FEA Study” - Dr Andrew Ang, Associate Professor, Swinburne University of Technology

“Computational Approach for Efficient Designing of Thermal Sprayed High Entropy Alloy Coatings” - Dr Spyros Kamnis, R&D Manager, Castolin Eutectic-Monitor Coatings

“Accelerating Material Design using Pretrained Large Language Models” - Dr Thorsten Stoltenhoff, Linde Advanced Material Technologies

“ExoGard® – High Performance Coatings for Hard Chrome Substitution” - Dibakor Boruah & Melissa Riley, TWI Ltd

“Developments in Thermal and Cold spraying at TWI Ltd” - Dr Adam Bennett, Cranfield Plasma Solutions

“Digitally Supported Plasma Processing” - Dr Jamie Pulsford, Metallisation Ltd

“Enhancing the Sustainability of HVOF Thermal Spraying using Hydrotreated Vegetable Oil (HVO)” - Dr Mark Cole, Laser Fusion Tech Ltd

“Influence of laser heating on adhesion and coating properties in Laser Assisted Cold Spray. Highlighting the Sustainability of this coating technology through improved quality and process efficiencies” - Andy Williams, Senior Engineering Fellow, Chromalloy UK

- James Hopper, Sales Team Lead UK, Oerlikon Balzers Coating UK Ltd

“A Complementary Sustainable Surface Engineering Approach Aligned with UK & EU REACH Legislation” - Mario Cordero-Cabrera, Welding Alloys Group

“Metal Cored Wires as a Fundamental Component in State-of-the-art Tailored Coating Solutions to Combat Materials Degradation” - Dr Stefan Zimmermann, Director of R&D, Lincotek Surface Solutions

“Suspension Sprayed Thermal Barrier Coatings Deposited by Advanced Cascaded Plasma Spray Technology”

Conference enquiries please contact:

Dr Andrew Cole

TSSEA Secretary

01788 522792

info@tssea.org

Sponsors

Dr Adam Bennett

Dr Bennett is the Director of Cranfield Plasma Solutions and a Visiting Lecturer at Cranfield University. Dr Bennett obtained a first degree and scored the equivalent of a first class on a taught Masters level course in Energy Beam Physics at the University of Cambridge, before undertaking a Doctorate in Applied Plasma Physics for Ultra-Precision Engineering at Cranfield University.

Dr Bennett’s expertise includes plasma characterisation, plasma surface interaction characterisation, plasma technology design and development, in situ plasma process monitoring, plasma parameter optimisation, and application development.

Currently Dr Bennett is working on projects with ADTEC Plasma Technology, the Manufacturing Technology Centre, and Cranfield University. Before the Corona Virus outbreak his primary focus was on the Solar Plasma Project, which was his own concept.

Since the Corona Virus outbreak, he has been working on a novel plasma technology solution for the sterilisation of surfaces in hospitals and ambulances.

Jamie Pulsford

Jamie Pulsford brings over three years of dedicated experience as a Research & Development Engineer at Metallisation Ltd. He has expertise in multiple thermal spray techniques including High-Velocity Oxygen Fuel (HVOF), Atmospheric Plasma Spray (APS), Twin Wire Arc Spray and Flame Spray.Prior to his tenure at

Metallisation Ltd, Jamie was a member of the Coatings and Surface Engineering group affiliated with the University of Nottingham. During this time, he pursued an Engineering doctorate which delved into the intricacies of ID-HVOF coatings. His doctoral research focused on the study of the microstructure and properties of these coatings and their sliding wear resistance.

Jamie’s expertise, honed through both academic research and industrial experience, highlight his proficiency and dedication to the advancement of surface engineering.

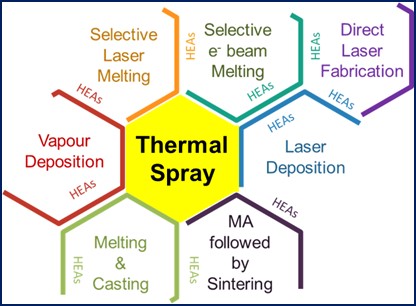

Computational Approach for Efficient Designing of Thermal Sprayed High Entropy Alloy Coatings

Dr Andrew Ang

The distinctive alloy design strategy and characteristics of high-entropy alloys (HEAs) have demonstrated immense promise for engineering applications, ranging from cryogenic to elevated temperatures. The combination of HEA and thermal spray technology has been further explored to develop robust and thick coatings for industrial applications operating in extreme engineering environments. However, the availability of diverse elemental combinations delimits the known experimental strategies for investigating the array of HEAs. Therefore, the incorporation of integrated computational material engineering within the conventional iterative HEAs design strategy plays a vital role in the efficient designing of HEAs. The phase compositions of thermal spray HEA coatings, which derives from non-equilibrium cooling conditions such as rapid solidification, can be predicted through the calculation of phase diagrams (CALPHAD) simulation approach. The research emphasizes the application of the CALPHAD method to proficiently construct the thermal spray HEA coatings, which were further verified using phase and microstructural analysis and substantiating their suitability in industrial environments.

ExoGard® – High Performance Coatings for Hard Chrome Substitution

Dr Thorsten Stoltenhoff

Since the entry into force of the EU Chemicals Regulation 1907/2006 – REACH on 1 June 2007 at the latest, many industrial sectors have been working increasingly on the substitution of electrodeposited chromium coatings, as the by-product – hexavalent chromium – is one of the prohibited substances. The substitution of g/a chrome coatings poses major challenges for both manufacturers and users due to their widespread use for decorative and technical purposes.

Many attempts to replace hard chrome coatings with Thermal Spray coatings have failed, as it was tried at the same time to achieve a significant improvement in the coating properties. Finally, the production costs of the resulting TS coatings got simply too high. A most suitable coating system as hard chrome substitute should therefore provide good protection against mechanical wear paired with sufficient corrosion resistance at a lowest possible total coating thickness. In addition, the as-coated surface should require lowest mechanical post-processing only. The extent to which this can be achieved with known or new technologies of thermal spraying will be presented here.

A Complementary Sustainable Surface Engineering Approach Aligned with UK & EU REACH Legislation

James Hopper

A major concern because of the ongoing REACH regulations continues to be the need to find alternatives to hard chrome plating (HCP) currently derived from chromic acid electroplating technologies.

HCP is widely used across a wide range of industries, including construction, oil & gas, aerospace, and defence. Its use is, however, restricted under REACH (and US OSHA) legislation due to the presence of highly toxic hexavalent chromium salts.

Many surface engineering companies have been working hard over the years to provide a functional replacement for HCP. Oerlikon are in a fortunate position to be able to provide a comprehensive range of coating technologies. The use of multiple available processes has therefore allowed Oerlikon to provide novel complementary & sustainable coating solutions to deal with the HCP environmental challenge. These solutions will be presented.

Metal Cored Wires as a Fundamental Component in State-of-the-art Tailored Coating Solutions to Combat Materials Degradation

Mario Cordero-Cabrera

The discussion will follow specific case studies where wear, corrosion, erosion, or combined mechanisms affect performance of engineering operations. It will also follow how fundamental understanding of the science behind those mechanisms is essential in designing the best solutions, how they are implemented, and how they prolong the life and performance of those components.